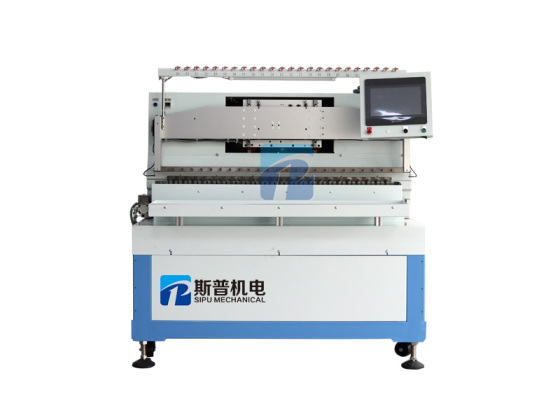

Linear Coil Winding Machine

A linear coil winding machine is a specialized equipment designed for the precise and efficient winding of coils. Automatic linear coil winding machine is used in the production of electromagnetic components like relays,transformers, inductors, and solenoids .

SIPU, a leading manufacturer, China CNC Coil Winding Machine Factory and Supplier, offering a wide range of models and customization options, cutting-edge CNC winding machines with reliable performance.

- Information

Linear Coil Winding Machine

Introduction:

Linear coil winding machines have become indispensable tools in various industries, playing a pivotal role in the production of relays, transformers, motors, and other electronic components.

SIPU linear winding technology – a particularly reliable solution, ideal for the manufacture of solenoid valves, relays, transformers, single element poles, current contactors, solenoid coils, inductors Vehicle solenoid,I Injector, Vehicle Sensor ,Vehicle Ignition,Power Supply Noise Filter,Sensor,Watch Coil,filter choke coil, antenna coils and speaker coils.

Linear Coil Winding Machine Video

Automatic multi-spindles linear coil Winding Machine Features

1. CNC AC servo motor transmission system, accuracy position control

2. Customize jig for easy replacement of winding fixtures.

3. The S3M wear-resistant synchronous belt is used to rotate, achieving high speed and bringing lower noise.

4.Visual touchscreen operation allows for easy program switching for different products.

5.A novel design, simple structure, easy operation and easy maintenance.

6.SIPU multi-spindles linear coil winding machine is made from high-quality materials, making it resistant to wear and tear.

7.SIPU linear coil winding Machine comes with a safety feature that automatically stops the machine when there is a malfunction.

8.Automatic multi-spindles linear coil Winding Machine can perform perfect layer winding.

9.Suitable for medium quantity and different type of small bobbin

Automatic Multi-spindles Linear Coil Winding Machine Technical Parameter

| Model | SPBZ23-A1B12 | SPBZ23-A1B16 | SPBZ23-A1B24 | SPBZ23-A1B32 |

| No. of Spindle | 12 Spindles | 16 Spindles | 24 Spindles | 32 Spindles |

| Spindle Pitch(mm) | 81mm | 60mm | 45mm | 31.5mm |

| Spindle Speed(rpm) | Max.15000rpm (CW/CCW) | Max.15000rpm (CW/CCW) | Max.18000rpm(CW/CCW) | Max.18000rpm(CW/CCW) |

Maximum Travel Distance | X-Axis 110mm (Front/Back) | X-Axis 110mm (Front/Back) | X-Axis 110mm(Front/Back) | X-Axis 110mm (Front/Back) |

| Y-Axis 110mm (Left/Right) | Y-Axis 110mm (Left/Right) | Y-Axis 110mm (Left/Right) | Y-Axis 110mm (Left/Right) | |

| Z-Axis 80mm (Up/Down) | Z-Axis 80mm (Up/Down) | Z-Axis 80mm (Up/Down) | Z-Axis 80mm (Up/Down) | |

| Controller | EtherCAT or RTEX controller | EtherCAT or RTEX controller | EtherCAT or RTEX controller | EtherCAT or RTEX controller |

| Wire Range(mm) | 0.02-0.4mm | 0.02-0.4mm | 0.02-0.4mm | 0.02-0.4mm |

| Power Source | AC380V 3P 50HZ or AC200V 3P 50/60HZ | AC380V 3P 50HZ or AC200V 3P 50/60HZ | AC380V 3P 50HZ or AC200V 3P 50/60HZ | AC380V 3P 50HZ or AC200V 3P 50/60HZ |

| Power Consumption | 2000W | 2000W | 2000W | 2000W |

| Air Pressure (Mpa) | 0.4Mpa~0.6Mpa | 0.4Mpa~0.6Mpa | 0.4Mpa~0.6Mpa | 0.4Mpa~0.6Mpa |

| Machine Size (mm) | 1300(W)×1250(D)×1270(H)mm | 1300(W)×1250(D)×1270(H)mm | 1300(W)×1250(D)×1270(H)mm | 1300(W)×1250(D)×1270(H)mm |

| Machine Weight (mm) | About 1100KG | About 1100KG | About 1100KG | About 1100KG |

Option | 1.Wire twister | 1.Wire twister | 1.Wire twister | 1.Wire twister |

| 2.Cutter | 2.Cutter | 2.Cutter | 2.Cutter | |

| 3.Automatic loading & unloading | 3.Automatic loading & unloading | 3.Automatic loading & unloading | 3.Automatic loading & unloading | |

| 4.Peeling device | 4.Peeling device | 4.Peeling device | 4.Peeling device | |

| 5.Electrical tensioner | 5.Electrical tensioner | 5.Electrical tensioner | 5.Electrical tension |

Our CNC Winding Machine Patent

...

...

About Us

Thank you for reaching out to us. We are pleased to introduce ourselves as the leading manufacturer and exporter of CNC Winding Machine,Automatic Coil Winding machines, Transformers Winding machines, Relay Winding Machine,Drum core inductor Winding machines, and Custom-built machines and so on.

We take pride in our diverse range of patents and innovations, catering to various coil winding needs. With a strong focus on research and development, we prioritize meeting our customers' requirements, providing bespoke solutions that surpass expectations.With our 3200 square meter factory, we maintain strict control over the entire production process, ensuring quality, price,efficiency, and timely delivery.Our winding machine team of experts are here to help you with all of the winding solutions with Semi-auto & Fully Automatic Winding solutions.

production: winding machine,motor winding mahcine,pin insetring, taping, soldering , coil taping mahice and fully automatic production.

Custom Solutions: Collaborate with our design team to receive personalized CNC winding machines tailored to your specific needs.

Superior Quality: Our products undergo rigorous testing for durability and quality control measures, ensuring durability and reliability in every machine we deliver.

Efficient Support: Our dedicated customer support team is readily available to answer inquiries, provide technical assistance, and ensure a seamless customer experience.