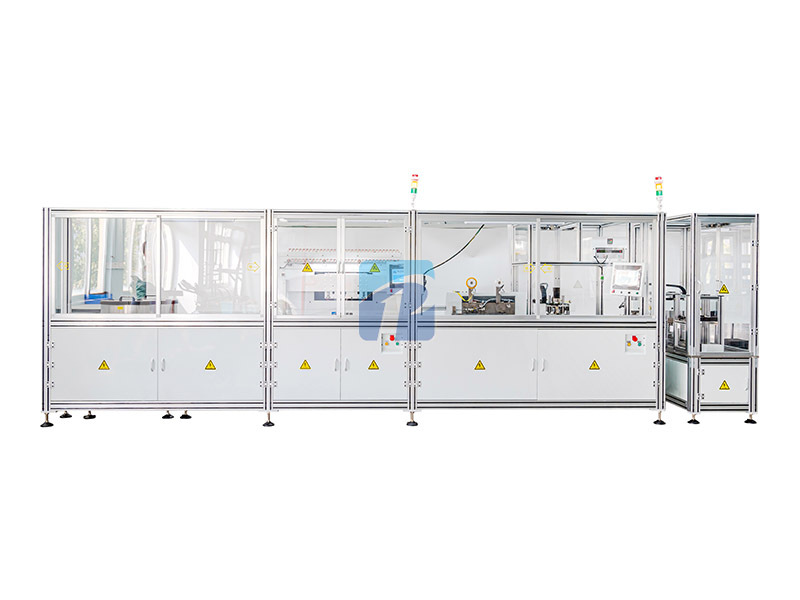

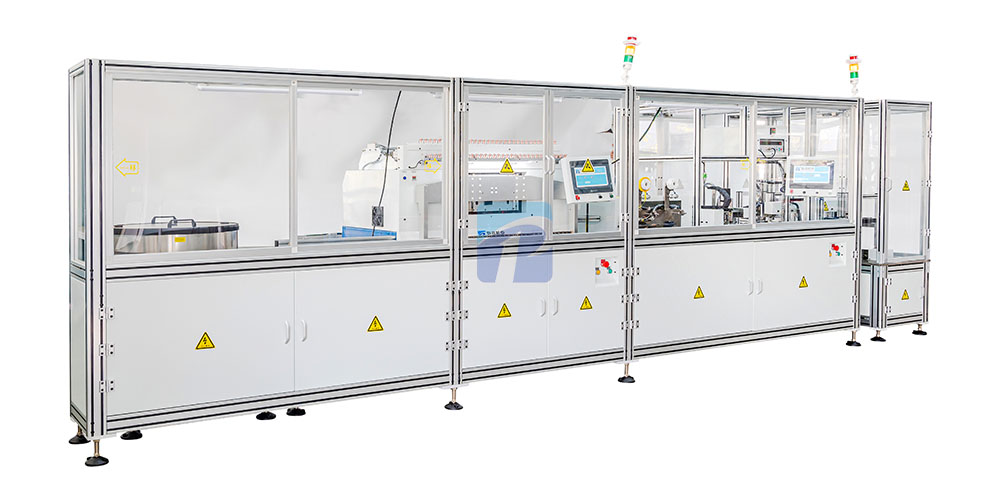

Fully Automatic Magnetic Coil Production Line

With the advanced features,our winding equipment provides a complete solution for the production of coil-wound components. The coil production line's automatic operation eliminates the need for manual labor, allowing for a streamlined and efficient production process.

- Information

Fully Automatic Magnetic Coil Production Line

Machine introduction

The fully automatic magnetic coil production line is a cutting-edge manufacturing system designed to produce magnetic coils with the highest level of precision, speed, and quality. The fully automatic magnetic coil production line is a game-changing technology that offers unprecedented levels of efficiency, versatility, and quality control, making it a highly sought-after solution in today's manufacturing industry.

Process

Auto bowl feeder→Pin inserting machine→Winding Machine→Soldering Machine→ Testing→Conveyor Unload

Machine Features

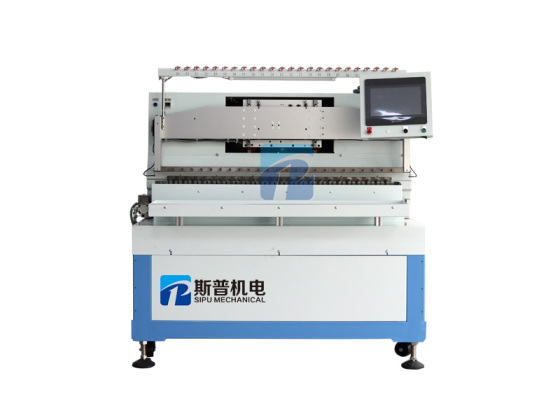

1.High-speed winding: Our production line is capable of winding coils at high speeds, ensuring that you can meet even the most demanding production schedules.

2.Precision accuracy: With advanced technology and precise controls, our production line can ensure that each coil is wound to exact specifications, eliminating errors and reducing waste.

3.Multiple take-up spools for increased production capacity

4.Modular design: The production line is modular in design, allowing for easy customization and upgrades to meet your specific needs.

5.High precision soldering: A fixture is used for soldering, controlled by a servo motor, which ensures high precision and consistency.

6.Low maintenance requirements for reduced operational costs

7.Integrated safety features for operator protection and workplace safety

8.Reliable performance: Our production line is built with high-quality components and is rigorously tested to ensure reliable performance and longevity.

Technical Parameter

| Model | SPBZ23-A3B32J |

| No. of Spindle | 32 Spindles |

| Spindle Pitch(mm) | 31.5mm |

| Spindle Speed(rpm) | Max.20000rpm (CW/CCW) |

Maximum Travel Distance | X-Axis 110mm (Front/Back) |

| Y-Axis 110mm (Left/Right) | |

| Z-Axis 80mm (Up/Down) | |

| Controller | EtherCAT or RTEX controller |

| Wire Range(mm) | 0.02-0.10mm |

| Power Source | AC380V 3P 50HZ or AC200V 3P 50/60HZ |

| Power Consumption | 5KW |

| Air Pressure (Mpa) | 0.45Mpa~0.65Mpa |

| Machine Size (mm) | 6000(W)×2500(D)×1800(H)mm |

| Machine Weight (mm) | About 2000KG |

Option | 1.Wire twister |

| 2.Cutter | |

| 3.Automatic loading & unloading | |

| 4.Peeling device | |

| 5.Electrical tensioner |