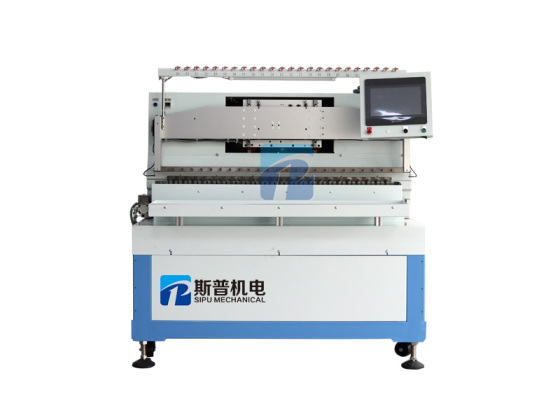

Fully Automatic Relay Coil Production Line

Investing in our fully automatic relay coil production line is a smart decision for companies looking to increase their production efficiency and output while maintaining high-quality standards. With advanced technology, precision accuracy, and user-friendly controls, our production line can help you stay ahead of the competition and achieve success in your industry.

- Information

- Video

Fully Automatic Relay Coil Production Line

Machine introduction

SIPU automatic relay production line is designed to meet the high production demands of various relay coils used in the communication, 3C universal, power, and automotive relay industries. With the ability to wind up to 32 coils simultaneously at a maximum speed of 20,000 RPM, our machine can produce up to 4,000 pieces per hour, ensuring optimal productivity for your business needs.

Process

Auto bowl feeder→Pin inserting machine→Winding Machine→Soldering Machine→Conveyor Unload

Machine Features

1.High Production Efficiency: With the ability to wind 32 coils simultaneously, our machine can achieve a maximum efficiency of 4,000 pieces per hour.

2.Fully Automatic Production: Our machine is designed to be fully automated, reducing the need for manual labor and improving product quality.

3.High-Speed Bearings: The winding axis is equipped with high-speed bearings that allow for a maximum speed of 20,000 RPM, ensuring precision and accuracy in coil manufacturing.

4.S2M Timing Belt: Our machine uses an S2M timing belt, which not only provides a high-speed operation but also reduces noise levels.

5.Easy to Maintain: The spindle belt is easily replaceable and requires minimal maintenance.

6.CNC Control Technology: Our coil winding machine is equipped with advanced CNC control technology that allows for easy programming and operation. The intuitive interface ensures even novice operators can use the machine with ease. You can easily set winding speed, turns, and direction according to different voltage requirements.

7.High-Quality Soldering: Before soldering, our machine applies an automatic flux applicator that improves the quality and stability of the soldering process.

8.Automated Testing: Our machine can automatically test the resistance of each coil and screen out any defective products.

Technical Parameter

| Model | SPBZ23-A3B32J |

| No. of Spindle | 32 Spindles |

| Spindle Pitch(mm) | 31.5mm |

| Spindle Speed(rpm) | Max.20000rpm (CW/CCW) |

Maximum Travel Distance | X-Axis 110mm (Front/Back) |

| Y-Axis 110mm (Left/Right) | |

| Z-Axis 80mm (Up/Down) | |

| Controller | EtherCAT or RTEX controller |

| Wire Range(mm) | 0.02-0.10mm |

| Power Source | AC380V 3P 50HZ or AC200V 3P 50/60HZ |

| Power Consumption | 5KW |

| Air Pressure (Mpa) | 0.45Mpa~0.65Mpa |

| Machine Size (mm) | 6000(W)×2500(D)×1800(H)mm |

| Machine Weight (mm) | About 2000KG |

Option | 1.Wire twister |

| 2.Cutter | |

| 3.Automatic loading & unloading | |

| 4.Peeling device | |

| 5.Electrical tensioner |