CNC Coil Winding Machine

SIPU, a leading manufacturer, offers cutting-edge CNC winding machines with reliable performance.

Offer:

OEM CNC Transformer Winding Machine: For high-quality transformer coils with precision and consistency.

CNC Automatic Coil Winder Winding Machine: Versatile automation for relay,motors, transformers, and fans.

CNC Ceiling Fan Winding Machine: Tailored for modern ceiling fan designs.

CNC Motor Winding Machine: Ideal for high-performance motor coils.

China CNC Coil Winding Machine Factory and Supplier.

China's manufacturing prowess has led to the emergence of several top-notch CNC winding machine factories and suppliers, offering a wide range of models and customization options.

CNC Winding Machine Manufacturers and Suppliers.

Globally recognized manufacturers and suppliers provide cutting-edge CNC winding machines equipped with the latest technology and features.

- Information

CNC Winding Machine

What is a CNC Winding Machine?

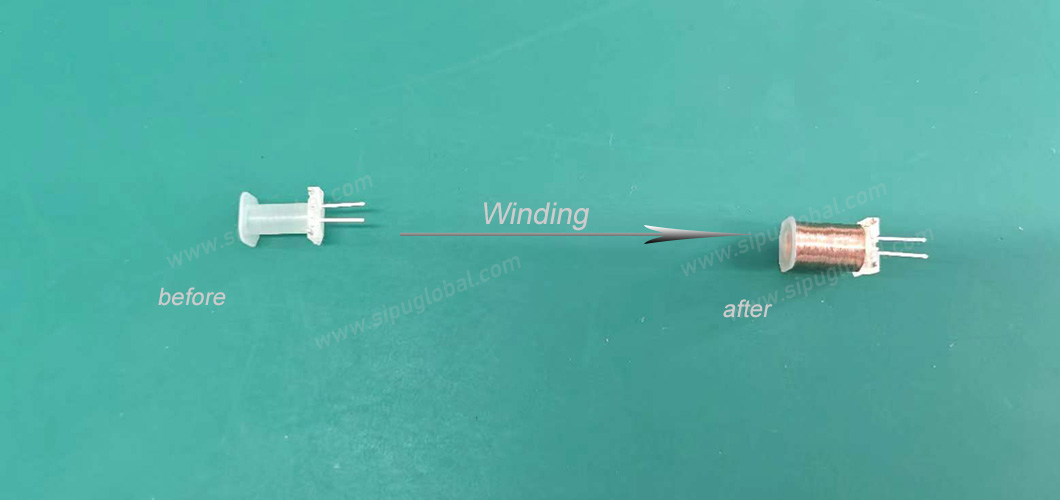

A CNC Winding Machine, also known as a coil winder machine, is an automated precision device that utilizes computer numerical control (CNC) systems to wind conductive materials like copper wire onto magnetic cores such as relays, solenoids, transformers, and inductors. This specialized coil winder machine executes complex winding patterns with high consistency, following pre-programmed parameters to ensure uniform layers, optimal tension, and precise alignment for electromagnetic components in industrial automation, robotics, and power electronics applications.

CNC Winding Machine introduction

Automatic 100% CNC Coil Winding Machine , designed to meet your industrial coil winding needs. This Coil Winder machine is engineered with the latest technology to provide precision and accuracy in winding coils.

With this automatic winding machine, you can easily wind coils of different shapes and sizes,such as use CNC Winding Machine winding relays, current contactors, solenoid coils, telecom transformers,small power transformers, signal transformers, inductors,Power transformer, Vehicle solenoid,In-vehicle relay, Injector, Vehicle Sensor ,Vehicle Ignition,Power Supply Noise Filter,Sensor,Watch Coil,filter choke coil.

CNC Coil Winding Machine Video

Q1: Where Does the CNC Winding Machine Find Applications in Manufacturing?

A1:The CNC Winding Machine is widely used in the manufacturing processes of the following electronic components,Such as:

Relay Winding Machine: Relays are crucial automatic control devices, and precision winding is vital for their functionality. The CNC Winding Machine efficiently and accurately winds relays, ensuring their reliable operation.

Transformers Winding Machine: Transformers are essential devices for voltage and current transformation. CNC Winding Machines can wind different types of transformers, enhancing their efficiency and performance.

Bobbin Winding Machine: Bobbins are integral parts of many electronic components. With a CNC Winding Machine, wires can be precisely wound onto bobbins, meeting specific application requirements.

Coil Winder for Inductors: Inductors are critical components for energy storage and filtering. A CNC Winding Machine ensures tight and uniform winding of inductors, improving their performance.

Some Case from our customers use our CNC Winding Machine

Q2: CNC Winding Machine Classification based on the Number of Axes

A2: CNC Winding Machines can be classified based on the number of axes they possess, including

Q3: Advantages of Customized Coil Winding Machines

A3: Customized Winding Machines offer the following advantages:

Tailored Solutions: Customized coil winding machines are designed to cater specifically to the unique requirements of the manufacturing process, ensuring optimal performance and efficiency.

Enhanced Productivity: Customized coil winding machines are optimized for the specific production needs, resulting in higher productivity and reduced downtime.

Cost Optimization: Customized coil winding machines are designed to minimize material waste and energy consumption, leading to cost-effective production.

Q4: Why Choose Customized CNC Coil Winding Machine?

A4:CNC Winding Machine

Production Capacity and Throughput:

Manufacturers are on the lookout for CNC Winding Machine with excellent production capacity and high throughput capabilities. These coil winding machine must handle substantial production volumes efficiently, without compromising on the quality of the end product. Meeting market demands for high-volume production is a critical factor for staying ahead in a competitive landscape.

Automation and Ease of Use:

Emphasizing automation and ease of use, manufacturers seek CNC Winding Machines with intuitive user interfaces and automated features. The reduction of manual intervention minimizes the need for skilled labor and significantly reduces the likelihood of errors. An easy-to-operate machine streamlines the training process for operators.

Adaptability to Different Coil Types:

The ability to handle diverse coil configurations is vital for manufacturers working with a wide range of electronic components. CNC Winding Machine should accommodate various coil types and sizes, allowing for versatile production processes. A single coil winding machine that caters to different coil configurations enhances overall efficiency and reduces setup time.

Material Handling and Waste Reduction:

Efficient material handling and waste reduction are paramount for resource optimization. Manufacturers prefer CNC Winding Machine that minimize material waste during the winding process. This not only reduces production costs but also promotes sustainable manufacturing practices.

Quality Control and Consistency:

Quality control and consistency are non-negotiable in the winding process. Manufacturers demand CNC Winding Machine that deliver precise winding specifications for each coil, adhering to strict quality standards. Consistent production of reliable and high-performance electronic components is essential for customer satisfaction.

Maintenance and Downtime:

Minimizing downtime and maintenance costs is a crucial consideration for manufacturers. Robustly constructed CNC Winding Machines with reliable components and straightforward maintenance procedures ensure smooth operation and enhanced production efficiency.

Integration with Existing Production Line:

Seamless integration with the existing production line is a priority for manufacturers to avoid disruptions in workflow. CNC Winding Machines should complement the current manufacturing processes, promoting an efficient and cohesive production environment.

Q5: Advantages of Customized Coil Winding Machines

A5: Customized Winding Machines offer the following advantages:

Tailored Solutions: Customized coil winding machines are designed to cater specifically to the unique requirements of the manufacturing process, ensuring optimal performance and efficiency.

Enhanced Productivity: Customized coil winding machines are optimized for the specific production needs, resulting in higher productivity and reduced downtime.

Cost Optimization: Customized coil winding machines are designed to minimize material waste and energy consumption, leading to cost-effective production.

CNC Winding Machine Features

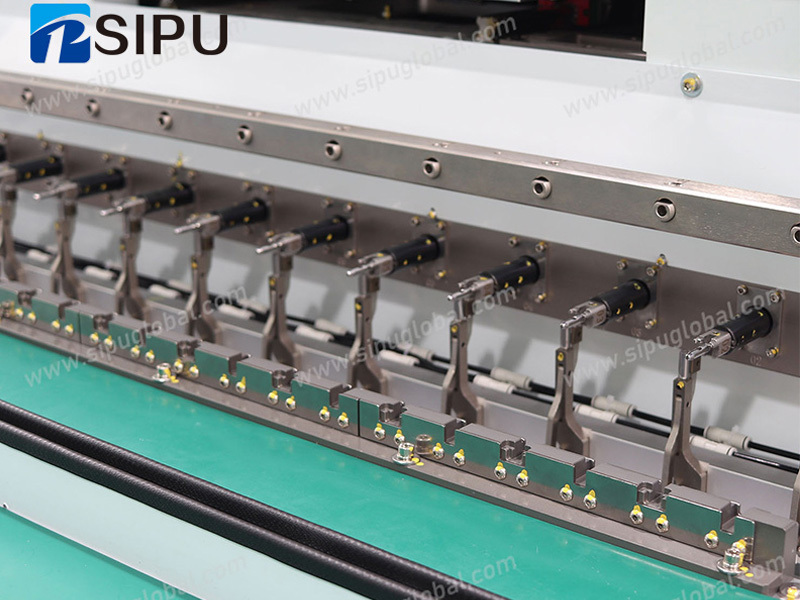

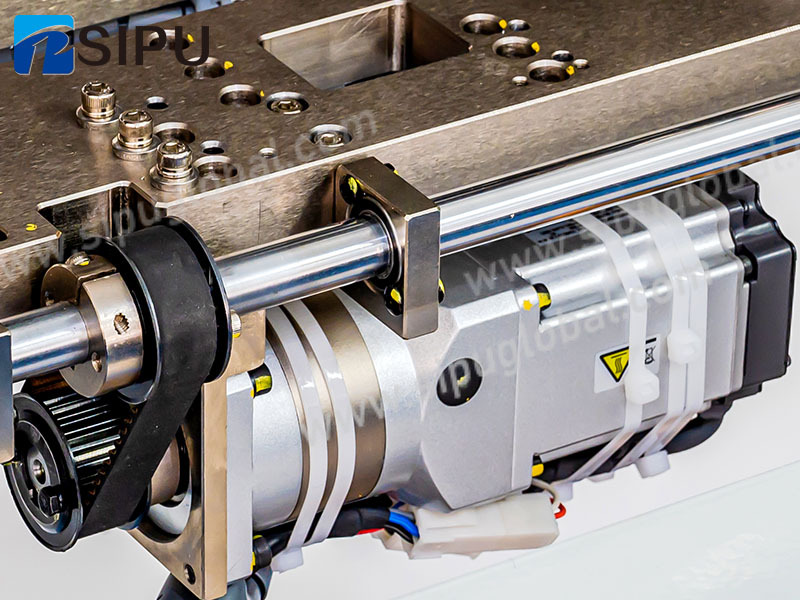

The auto coil winding machine is designed with CNC technology, easy to program and operate.

Customize jig for easy replacement of winding fixtures.

The S3M wear-resistant synchronous belt is used to rotate, achieving high speed and bringing lower noise.

The CNC Winding Machine intuitive interface ensures that even novice operators can use the machine with ease.

SIPU Coil CNC Winding Machine is equipped with a robust and durable construction, ensuring longevity and reliability.

SIPU CNC winding machine is made from high-quality materials, making it resistant to wear and tear.

SIPU CNC winding Machine comes with a safety feature that automatically stops the machine when there is a malfunction.

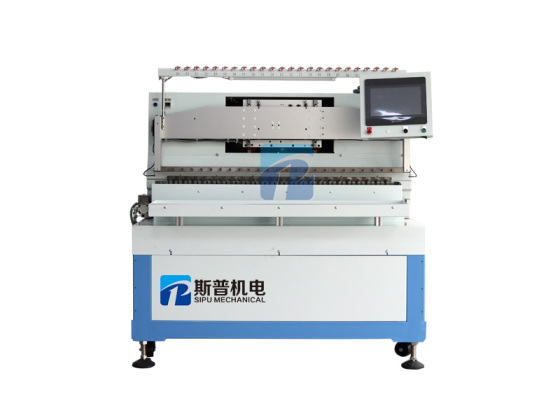

CNC Winding Machine Technical Parameter

| Model | SPBZ23-A1B12 | SPBZ23-A1B16 | SPBZ23-A1B24 | SPBZ23-A1B32 |

| No. of Spindle | 12 Spindles | 16 Spindles | 24 Spindles | 32 Spindles |

| Spindle Pitch(mm) | 81mm | 60mm | 45mm | 31.5mm |

| Spindle Speed(rpm) | Max.15000rpm (CW/CCW) | Max.15000rpm (CW/CCW) | Max.18000rpm(CW/CCW) | Max.18000rpm(CW/CCW) |

Maximum Travel Distance | X-Axis 110mm (Front/Back) | X-Axis 110mm (Front/Back) | X-Axis 110mm(Front/Back) | X-Axis 110mm (Front/Back) |

| Y-Axis 110mm (Left/Right) | Y-Axis 110mm (Left/Right) | Y-Axis 110mm (Left/Right) | Y-Axis 110mm (Left/Right) | |

| Z-Axis 80mm (Up/Down) | Z-Axis 80mm (Up/Down) | Z-Axis 80mm (Up/Down) | Z-Axis 80mm (Up/Down) | |

| Controller | EtherCAT or RTEX controller | EtherCAT or RTEX controller | EtherCAT or RTEX controller | EtherCAT or RTEX controller |

| Wire Range(mm) | 0.02-0.4mm | 0.02-0.4mm | 0.02-0.4mm | 0.02-0.4mm |

| Power Source | AC380V 3P 50HZ or AC200V 3P 50/60HZ | AC380V 3P 50HZ or AC200V 3P 50/60HZ | AC380V 3P 50HZ or AC200V 3P 50/60HZ | AC380V 3P 50HZ or AC200V 3P 50/60HZ |

| Power Consumption | 2000W | 2000W | 2000W | 2000W |

| Air Pressure (Mpa) | 0.4Mpa~0.6Mpa | 0.4Mpa~0.6Mpa | 0.4Mpa~0.6Mpa | 0.4Mpa~0.6Mpa |

| Machine Size (mm) | 1300(W)×1250(D)×1270(H)mm | 1300(W)×1250(D)×1270(H)mm | 1300(W)×1250(D)×1270(H)mm | 1300(W)×1250(D)×1270(H)mm |

| Machine Weight (mm) | About 1100KG | About 1100KG | About 1100KG | About 1100KG |

Option | 1.Wire twister | 1.Wire twister | 1.Wire twister | 1.Wire twister |

| 2.Cutter | 2.Cutter | 2.Cutter | 2.Cutter | |

| 3.Automatic loading & unloading | 3.Automatic loading & unloading | 3.Automatic loading & unloading | 3.Automatic loading & unloading | |

| 4.Peeling device | 4.Peeling device | 4.Peeling device | 4.Peeling device | |

| 5.Electrical tensioner | 5.Electrical tensioner | 5.Electrical tensioner | 5.Electrical tension |

Our CNC Winding Machine Patent

...

...

About Us

Thank you for reaching out to us. We are pleased to introduce ourselves as the leading manufacturer and exporter of CNC Winding Machine,Automatic Coil Winding machines, Transformers Winding machines, Relay Winding Machine,Drum core inductor Winding machines, and Custom-built machines and so on.

We take pride in our diverse range of patents and innovations, catering to various coil winding needs. With a strong focus on research and development, we prioritize meeting our customers' requirements, providing bespoke solutions that surpass expectations.With our 3200 square meter factory, we maintain strict control over the entire production process, ensuring quality, price,efficiency, and timely delivery.Our winding machine team of experts are here to help you with all of the winding solutions with Semi-auto & Fully Automatic Winding solutions.

production: winding machine,motor winding mahcine,pin insetring, taping, soldering , coil taping mahice and fully automatic production.

Custom Solutions: Collaborate with our design team to receive personalized CNC winding machines tailored to your specific needs.

Superior Quality: Our products undergo rigorous testing for durability and quality control measures, ensuring durability and reliability in every machine we deliver.

Efficient Support: Our dedicated customer support team is readily available to answer inquiries, provide technical assistance, and ensure a seamless customer experience.