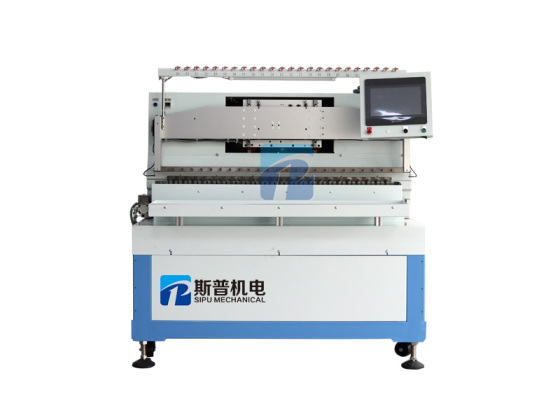

Transformer Winding Machine

SIPU, a leading manufacturer, offers advanced coil winding machines that deliver reliable performance.

Offer: Winding machine and various winding solutions, equipment required for automatic winding,such as taping machine,pin-inserting-machine, Soldering Machine and so on.

Transformer Winding Machine: Ensuring high-quality transformer coils with precision and consistency. Automatic Coil Winder Winding Machine: Offering versatile automation for relays, motors, transformers, and fans. Ceiling Fan Winding Machine: Tailored specifically for modern ceiling fan designs. Motor Winding Machine: Ideal choice for high-performance motor coils.

Coil Winding Machine Factory and Supplier China's manufacturing expertise has given rise to numerous top-tier CNC winding machine factories and suppliers, providing a wide range of models and customization options.

- Information

Transformer Winding Machine

Transformer Coil Winding Machines

One of the key components in transformer manufacturing is the winding process, and this is where transformer winding machines come into play.

A. Explanation of the basic components and features

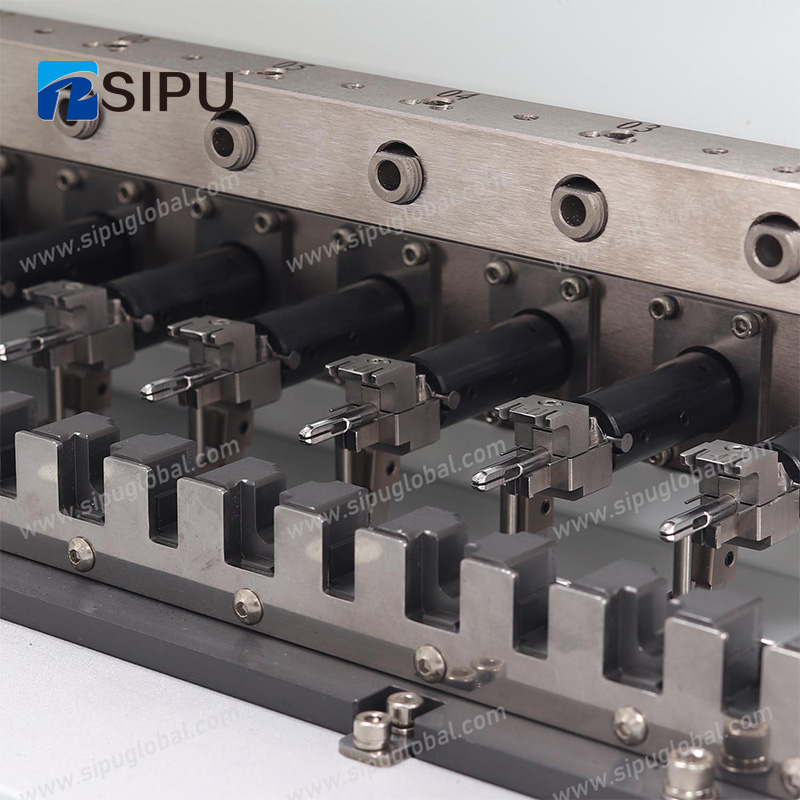

1. Core winding assembly:

The core winding assembly is a fundamental component of a transformer winding machine.

It consists of a robust frame that supports the transformer core during the winding process.

The core winding assembly is designed to accommodate various core sizes and shapes, allowing for versatility in transformer production.

It ensures the stability and alignment of the core, which is essential for achieving accurate and uniform winding.

2. Coil winding system:

The coil winding system is responsible for precisely winding the copper or aluminum wire onto the transformer core. It consists of a spindle, which holds the wire spool, and a winding head, which guides the wire onto the core.

The winding head moves along the core, ensuring an even distribution of the wire and maintaining the required tension throughout the winding process.

The coil winding system can be adjusted to accommodate different wire gauges and winding patterns, allowing for flexibility in transformer design.

3. Tensioning and guiding mechanisms:

Tensioning and guiding mechanisms are crucial for maintaining the proper tension and alignment of the wire during winding.

They ensure that the wire is wound tightly and evenly, minimizing the risk of short circuits or insulation failures.

Tensioning mechanisms typically involve the use of tensioning arms or pulleys, which apply a controlled amount of tension to the wire.

Guiding mechanisms, on the other hand, ensure that the wire follows the desired path and does not deviate from the winding pattern.

4. Control and automation systems:

Modern transformer winding machines are equipped with advanced control and automation systems.

These systems allow for precise control of various parameters, such as winding speed, tension, and wire alignment.

They also enable the programming of complex winding patterns and the storage of multiple winding configurations for different transformer models.

The control and automation systems enhance the efficiency and accuracy of the winding process, reducing human errors and increasing productivity.

5. Safety features and precautions:

Transformer winding machines are equipped with several safety features to protect operators and prevent accidents.

These features may include emergency stop buttons, safety interlocks, and protective enclosures.

Operators are required to follow strict safety procedures, such as wearing personal protective equipment and undergoing training on machine operation and maintenance.

Adherence to safety precautions is essential to ensure a safe working environment and minimize the risk of injuries.

Transformer Winding Machine introduction

Section 1: Classification of Transformers

Q1: What are the main categories of transformers based on their applications?

A1: Transformers can be broadly classified into power transformers, distribution transformers, instrument transformers, and specialty transformers.

Q2: How are transformers classified based on their winding configuration?

A2: Transformers are categorized into single-phase and three-phase transformers, each with its own set of winding arrangements.

Section 2: Categories of Transformer Winding Machines

Q3: What are the different types of transformer winding machines available?

A3: Transformer winding machines are classified into four main categories: manual winding machines, semi-automatic winding machines,

fully automatic winding machines, and CNC winding machines.

Manual Winding Machines: Basic machines operated by human intervention, suitable for low-volume production.

Semi-Automatic Winding Machines: Combine manual and automated features, enhancing efficiency and precision.

Fully Automatic Winding Machines: Highly automated machines that handle most aspects of winding, ideal for medium to high production volumes.

CNC Winding Machines: Advanced computer numerical control machines that offer unparalleled precision and customization options.

Q4:How much does a Transformer Winding Machine cost?

A4:The cost of a Transformer Winding Machine can vary widely depending on its size, capabilities, and complexity.

Prices for these machines typically range from US $0.1 to $100,000 per set.

It is crucial to conduct thorough research and compare different models and features to find the best Transformer Winding Machine that suits both your needs and budget.

Q5:What factory makes Transformer Winding Machines?

A5:There are numerous factories worldwide that manufacture Transformer Winding Machines. One popular manufacturer is Xiamen SIPU Mechanical Co., Ltd.

However, there are also many other smaller manufacturers and specialized companies that produce Transformer Winding Machines for specific industries or applications.

It is advisable to explore different options and consider factors such as reputation, reliability, and customer reviews when selecting a manufacturer.

Q6:How do I choose a Transformer Winding Machine?

A6:Choosing the right Transformer Winding Machine can be a daunting task, but considering a few key factors can help you make an informed decision.

Firstly, determine the type of Transformer Winding Machine that suits your requirements.

Secondly, consider the materials and functions it offers, ensuring they align with your specific needs.

Additionally, evaluate the purpose and use of the machine, as well as the maintenance and support it requires.Lastly, establish a budget and choose a machine that fits within your financial constraints.

Q7:How many types of Transformer Winding Machines are there?

A7:Transformer Winding Machines can be classified into various types based on their functions or purposes.

The specific type of machine used will depend on the requirements of the production process and the type of product being produced.

It is essential to be honest about your volume of production and select a Transformer Winding Machine that is designed to meet the needs of your business.

By considering factors such as capacity, efficiency, and precision, you can identify the most suitable type of machine for your specific application.

Some Case from Transformer Winding Machine Prouduce

Q8: Why Choose SIPU Transformer Winding Machine?

A8:SIPU Transformer Winding Machine features

1.Novel design, simple structure, strong rigidity, simple operation and easy maintenance

2.Programmed by computer or touch screen, free to choose on the quick coupling fixture to save the time of changing different models

3.0°,90°,135° nozzle bars are optional to install to faciitate the winding of bobbins through different angles Use precision tension unit with back tension control to make the wire more tidy when aligning

■ With optional automatic loading and unloading function to greatly save the time of winding

■ With optional automatic twisting wire function to improve the stability of the products and to meet special requirements of the products Automatically clamp, pull apart and remove the wasted wire

■ With password saving function to avoid the modification of program by non-related personnel

Our Transformer Winding Machine Patent

About Us

Thank you for reaching out to us. We are pleased to introduce ourselves as the leading manufacturer and exporter of Transformers Winding machines, CNC Winding Machine,Automatic Coil Winding machines,Relay Winding Machine,Drum core inductor Winding machines, and Custom-built machines and so on.

We take pride in our diverse range of patents and innovations, catering to various coil winding needs. With a strong focus on research and development, we prioritize meeting our customers' requirements, providing bespoke solutions that surpass expectations.With our 3200 square meter factory, we maintain strict control over the entire production process, ensuring quality, price,efficiency, and timely delivery.Our winding machine team of experts are here to help you with all of the winding solutions with Semi-auto & Fully Automatic Winding solutions.

production: winding machine,motor winding mahcine,pin insetring, taping, soldering , coil taping mahice and fully automatic production.

Custom Solutions: Collaborate with our design team to receive personalized CNC winding machines tailored to your specific needs.

Superior Quality: Our products undergo rigorous testing for durability and quality control measures, ensuring durability and reliability in every machine we deliver.

Efficient Support: Our dedicated customer support team is readily available to answer inquiries, provide technical assistance, and ensure a seamless customer experience.