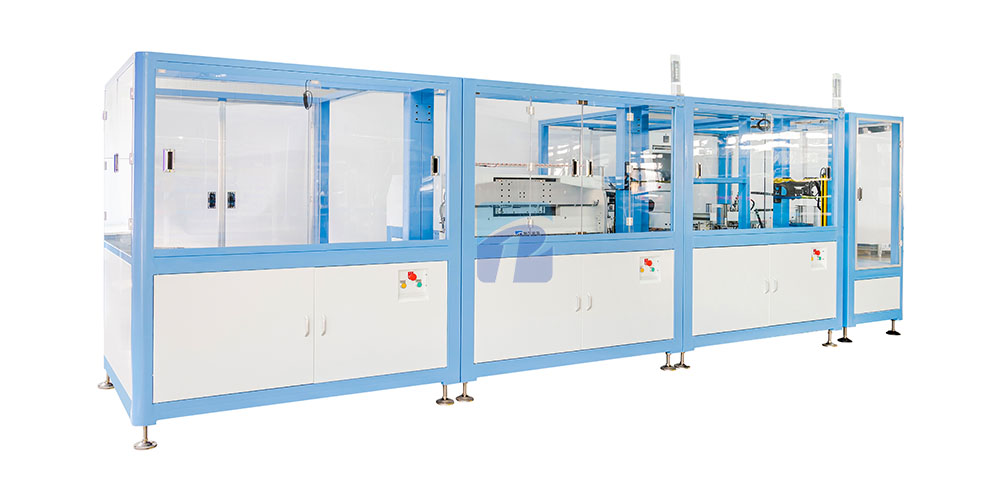

Fully Automatic Stepper Motor Coil Production Line

Our fully automatic coil winding is a reliable and efficient solution for manufacturers looking to improve their production capabilities. With its advanced features and reliable performance, this Coil manufacturing equipment is sure to meet the demands of even the most challenging production environments.

- Information

Fully Automatic Stepper Motor Coil Production Line

Machine introduction

SIPU's fully automatic stepper motor coil production line adopts highly integrated precision winding technology to adapt to the flexible production needs of multi-pole synchronous motor coils. The intelligent control system realizes the full process automation of coil winding, insulation treatment and performance testing, and can quickly switch production specifications to meet the large-scale manufacturing needs of high-precision motor core components in smart home, industrial equipment and consumer electronics. (For example, various products such as automatic mahjong tables, rotating camera motors and automatic curtain motors.)

The equipment is specially designed for the high production efficiency required in Solenoid production lines, with the ability to wind up to 16 coils simultaneously. With a maximum speed of 15,000 RPM, our machines can produce up to 1,200 units per hour.

Process

Auto bowl feeder→Pin inserting machine→Coil Winding Machine→ Coil Taping Machine→Soldering Machine→ Testing→Terminal Cover Installation→Conveyor Unload

Benefits

• Increased Productivity: The fully automatic production line significantly reduces production time and labor costs, resulting in higher productivity and cost savings.

• Improved Product Quality: The advanced manufacturing technology and strict quality control measures ensure consistent product quality, reducing the risk of product failure and improving customer satisfaction.

• Enhanced Flexibility: The ability to quickly switch between different production models and customize production parameters makes the production line highly flexible, enabling manufacturers to respond quickly to market changes and customer demands.

Machine Features

1.Fully automated production: The winding machine is designed with CNC control technology for easy programming and operation.

2.The user-friendly interface ensures even novice operators can easily use the machine.

3.High-speed bearing installation: The winding shaft is installed with high-speed bearings, which can achieve a maximum speed of 15000RPM.

4.The use of a durable synchronous belt ensures high speed and low noise. The main spindle belt is easy to replace and maintain.

5.Automatic soldering function: The machine has an automatic solder paste application function before soldering, which improves soldering quality and stability.

6.Automatic resistance testing: The machine can automatically test the coil resistance and screen out defective products.

7.Automatic tray loading: The machine has an automatic tray loading function that can stack 12 empty trays and full trays at once.

8.Automatic error detection and shutdown for improved safety.

Technical Parameter

| Model | SPBZ23-A3B16 |

| No. of Spindle | 16 Spindles |

| Spindle Pitch(mm) | 60mm |

| Spindle Speed(rpm) | Max.15000rpm (CW/CCW) |

Maximum Travel Distance | X-Axis 110mm (Front/Back) |

| Y-Axis 110mm (Left/Right) | |

| Z-Axis 80mm (Up/Down) | |

| Controller | EtherCAT or RTEX controller |

| Wire Range(mm) | 0.02-0.20mm |

| Power Source | AC380V 3P 50HZ or AC200V 3P 50/60HZ |

| Power Consumption | 5KW |

| Air Pressure (Mpa) | 0.45Mpa~0.65Mpa |

| Machine Size (mm) | 6000(W)×2500(D)×1800(H)mm |

| Machine Weight (mm) | About 2000KG |

Option | 1.Wire twister |

| 2.Cutter | |

| 3.Automatic loading & unloading | |

| 4.Peeling device | |

| 5.Winding tensioner |