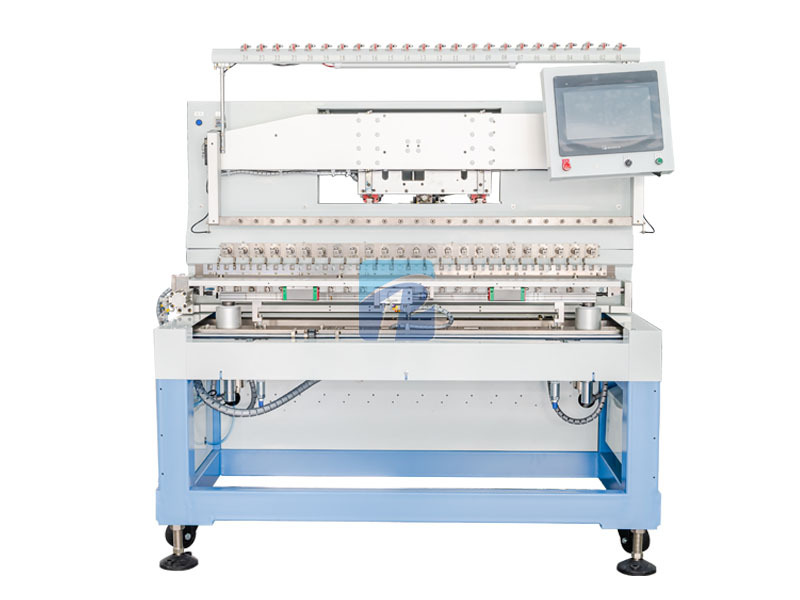

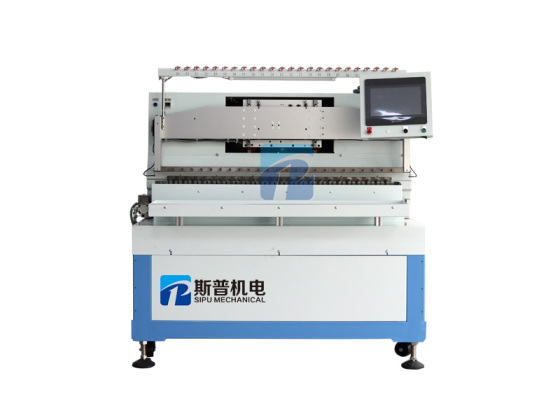

24 spindles Winding Machine

Our fully automatic coil winding machine is designed to efficiently produce high-quality wire-wound components . With a range of advanced features, this machine is perfect for manufacturers looking to increase productivity and reduce labor costs.

- Information

24 Spindles Winding Machine

Machine introduction

The 24 spindles winding machine is a cutting-edge machine designed for the precise and efficient winding of coils. This windging machine is equipped with advanced technologies such as CNC winding, automatic linear winding, and precision winding, which enable high-volume production of high-quality solenoids.

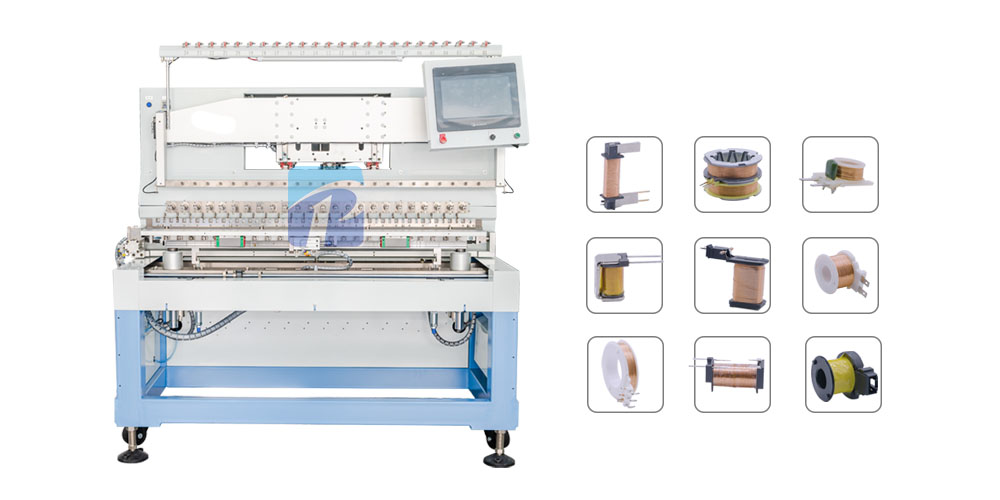

This type of machine is highly automated and can be programmed to wind coils of different sizes and shapes.such as relays, current contactors, solenoid coils, inductor coil, filter choke coil,lens coil, transformer coil, inverter coil, valve coil, ignition coil, adapter coil, switch coil,car horn coil, primary coil, mirror coil and various related coil etc.The precision winding machine is also capable of maintaining consistent tension and spacing between windings, ensuring that the finished coil meets the required specifications.

Machine Features

1.The windging Machine can perform perfect layer winding.

2..The windging Machine equips with CNC 4-axis AC servo motor transmission system, accuracy position control.

3.Equipped with state-of-the-art features, this machine provides precise control over wire tension, wire feed, and winding speed.

4.Winding shafts use high-speed bearings for a maximum speed of 18,000 RPM and S2M wear-resistant synchronous belts to achieve high speeds with low noise.

5.Modular design, can add tape wrapping device, cutter device, paint peeling device, twisting device, etc. .

6.The winding machine offers highly customizable settings to cater to specific client needs, and can be easily programmed to produce different coil configuration.

7.Durable Construction: The machine is constructed with high-quality materials and is designed to withstand the demands of continuous use, making it a reliable choice for long-term production needs.

8.Equipped with a fault-detection system, which will automatically detect problems or malfunctions and alarm the operator.

Technical Parameter

| Model | SPBZ23-A1B24 |

| No. of Spindle | 24 Spindles |

| Spindle Pitch(mm) | 45mm |

| Spindle Speed(rpm) | Max.18000rpm (CW/CCW) |

Maximum Travel Distance | X-Axis 110mm (Front/Back) |

| Y-Axis 110mm (Left/Right) | |

| Z-Axis 80mm (Up/Down) | |

| Controller | EtherCAT or RTEX controller |

| Wire Range(mm) | 0.02-0.4mm |

| Power Source | AC380V 3P 50HZ or AC200V 3P 50/60HZ |

| Power Consumption | 2000W |

| Air Pressure (Mpa) | 0.45Mpa~0.65Mpa |

| Machine Size (mm) | 1300(W)×1250(D)×1270(H)mm |

| Machine Weight (mm) | About 1100KG |

Option | 1.Wire twister |

| 2.Cutter | |

| 3.Automatic loading & unloading | |

| 4.Peeling device | |

| 5.Electrical tensioner |