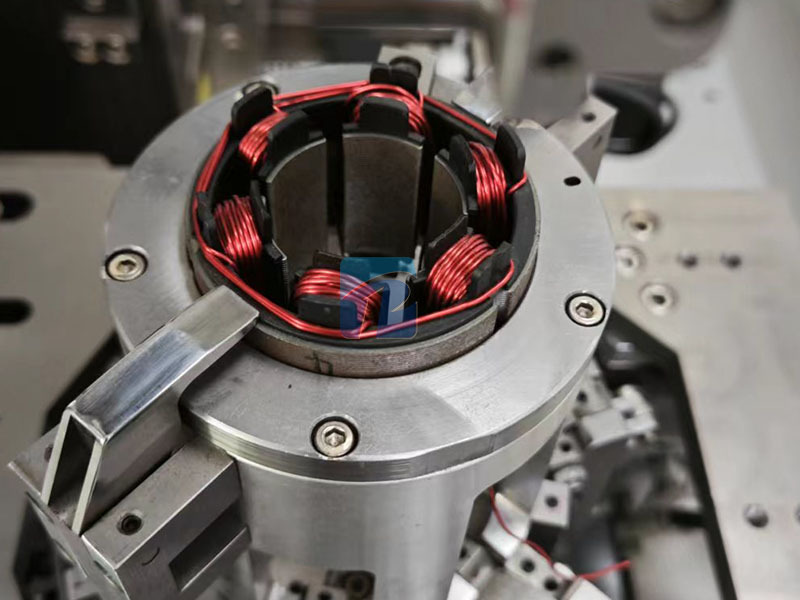

Automatic Stator Winding Machine

The Automatic Stator Winding Machine is a highly efficient and precise machine designed for winding stators of various sizes and types. The Stator Winding Machine is ideal for use in the manufacturing of various cooling fans, DC brushless motors, magneto stators, electric motors, generators, transformers and other micro-motor.The Automatic Stator Winding Machine can complete the winding process in a matter of minutes, reducing production time and increasing efficiency.

- Information

Automatic Stator Winding Machine

Machine introduction

Automatic Stator Winding Machine is a high-performance machine designed for winding coils on block-type electric motor stators. The modular stator winding machine is an ideal choice for various applications, including elevator systems and other machinery. This motor winding machine is equipped with advanced features that ensure precision and efficiency, delivering optimal results every time. Ideal for industries requiring mass production and consistent quality, this machine combines advanced technology with user-friendly operation to deliver unmatched performance.

FAQ

Q1:Where Does the Automatic Stator Winding Machine Find Applications in Manufacturing?

A1:The Automatic Stator Winding Machine is widely applicable to automotive, home appliances, or renewable energy, this machine plays a vital role in driving innovation and productivity.

Q2:What are the benefits of the Automatic Stator Winding Machine?

A2:The Automatic Stator Winding Machine offers numerous benefits that make it an indispensable tool in modern manufacturing. Below are the key benefits:

1. Increased Productivity

High-Speed Operation: Capable of winding stators at exceptional speeds, significantly reducing production time.

Automation: Eliminates the need for manual winding, allowing for continuous operation and higher output.

2. Consistent Quality

Precision Control: Equipped with advanced servo motors and CNC systems to ensure uniform winding tension and patterns.

Reduced Human Error: Automates the winding process, minimizing inconsistencies and defects.

3. Cost-Effectiveness

Labor Savings: Reduces the need for skilled labor, lowering operational costs.

Material Efficiency: Minimizes wire waste through precise control over winding tension and patterns.

Lower Maintenance: Designed for durability and reliability, reducing downtime and maintenance costs.

4. Versatility

Wide Range of Applications: Compatible with various stator sizes and wire types, making it suitable for multiple industries.

Customizable: Can be tailored to meet specific production requirements, such as different winding patterns or speeds.

5. Improved Efficiency

Quick Setup: Easy to program and adjust for different stator designs, reducing setup time.

Continuous Operation: Capable of running 24/7 with minimal supervision, maximizing production efficiency.

6. Enhanced Performance

High-Quality Windings: Ensures optimal performance of electric motors by providing consistent and precise windings.

Reliability: Produces stators with high reliability and durability, essential for critical applications like electric vehicles and industrial equipment.

7. User-Friendly Operation

Intuitive Interface: Features a touchscreen interface for easy programming and operation.

Multiple Language Support: Accommodates global users with multilingual options.

8. Scalability

Mass Production: Ideal for high-volume production, making it suitable for large-scale manufacturing.

Flexibility: Can handle both small and large production runs, providing scalability for growing businesses.

9. Global Support

Comprehensive Service: Offers worldwide after-sales support, including installation, training, and maintenance.

Technical Expertise: Backed by years of experience in designing and manufacturing winding machines.

Machine Features

1.Motion control card with up to 100 programs for flexibility

2.Specialized core for easy wire placement

3.Automatic cutting and clamping mechanisms for simplified production

4.Electronic tension control for reliable and stable performance

5.Rapid tool change feature for quick and easy switching between production tools

6.Multiple machines can be easily synced and programmed for consistent performance

Technical Parameter

| Model | JPX-G2-300 |

| Number of stations | 2 |

| Spindle Pitch(mm) | 200mm/300mm/400mm |

| Spindle Speed(rpm) | Max.1000rpm (CW/CCW) |

| Controller | PLC+CNC Control |

| Counting accuracy | 0.1° |

| Wire Range(mm) | 0.19-1.2mm |

| Power Source | AC380V 3P 50HZ or AC200V 3P 50/60HZ |

| Air Pressure (Mpa) | 0.4Mpa~0.7Mpa |

Application | magneto stators,transformers,block motors,wheel motors,robot drive motors,new energy motors, etc. |