- Home

- >

- Products

- >

- Magnetic Tensioner

- >

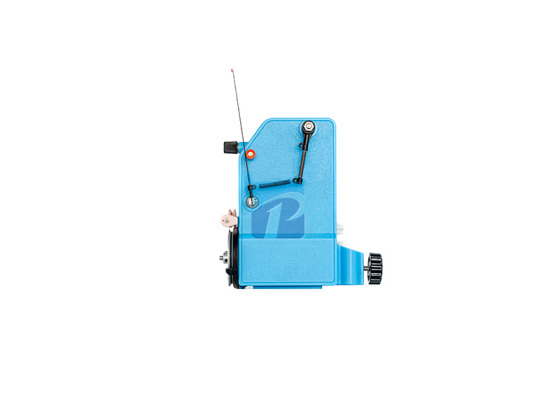

Magnetic Tensioner

The magnetic tensioners are essential components in the wire winding industry and have a wide range of uses, making magnetic wire tensioners the first choice for many applications. Coil winding magnetic tensioners offer high accuracy, long-term stability and excellent performance, making them a reliable and efficient choice for wire tension control. The device combines advanced magnetic field modulation technology with a zero mechanical wear design, making it suitable for coil winding in automotive electronics, medical devices and industrial transformers.

- Information

Coil winding magnetic tensioner

Introduction

SIPU's magnetic tensioner is equipped with an innovative magnetic tension control system, using high-performance permanent magnets and advanced magnetic field modulation technology to maintain consistent tension output during the production process. This type of tensioner frictionless design minimizes mechanical wear and is ideal for high-speed automated production lines. This magnetic tensioner provides reliable torque control and becomes an indispensable part of the coil production line, while being suitable for different industrial fields.

Features

1.The coil winding magnetic tensioner is the key component to control the adjustable tension during the coil be winding.Magnetic tensioner is an advanced wire tension control device that utilizes magnetic torque to produce damping without mechanical friction. As a result, the magnetic tensioner can generate stable and precise tension for a long time, with excellent accuracy.

2.The coil winding magnetic tensioner can freely adjust the reverse tension, making it suitable for winding square frames and wires with rapidly changing winding speeds without producing continuity problems.

3.The magnetic tensioner is highly reliable and provides excellent wire tension control, and its accuracy can be effectively ensured. The winding magnetic tensioner eliminates wire slippage and other problems that occur in mechanical friction-based tensioners. This tensioner is highly beneficial for maintaining uniform winding tension and avoiding wire breaks.

Applications:

The magnetic tensioner has become a key piece of equipment in the field of coil winding with its non-contact magnetic field tension control technology. It effectively solves the problem of easy wear and reduced precision of traditional mechanical tensioners by adjusting the wire tension in real-time, and is especially suitable for scenarios with strict requirements on winding uniformity. The following are its core application fields:

Motor manufacturing: Magnetic tensioners are widely used in the production of stepper motors,servo motors, and brushless DC motors (BLDC): used to wind stator or rotor coils to ensure tight and uniform winding, reduce the risk of inter-turn short circuits, and improve motor efficiency and life.

Transformers and relays: This tensioner is suitable for the production of power transformers, electromagnetic relays, and automotive relays, ensuring high consistency of coil winding while ensuring product quality.

Automated winding equipment: By integrating with automated production lines, magnetic tensioners enable high-speed, high-precision winding.

Sensor coils: Magnetic tensioners wind micro-coils in electromagnetic sensors, ensuring high sensitivity and consistency.

New energy field: it is adaptable to high-torque applications and complex winding structures such as wind turbines.

Industrial and consumer electronics: the magnetic tensioner can be used in relay or contactor mass production to improve the yield of electromagnetic components in home appliances.

Technical Parameters

| Model | Use Wire Rang (mm) | Tension Rang(g) |

| MTA-30 | 0.02~0.08 | 3~30 |

| MTA-100 | 0.04~0.12 | 10~100 |

| MTA-200 | 0.06~0.16 | 25~200 |

| MTA-400 | 0.08~0.25 | 50~400 |

| MTA-600 | 0.12~0.35 | 80~600 |

| MTA-800 | 0.14~0.50 | 100~800 |