Electric Welding Equipment

The resistance welding system is a reliable and efficient solution for joining terminal parts of electrical components. With its automatic operation, stable welding quality, and flexible welding options,The electric soldering machine is an essential tool for many industries. Whether you are working in manufacturing, automotive repair, or construction, the resistance welding machine can help you achieve strong and durable welds with ease.

- Information

Electric Welding Equipment

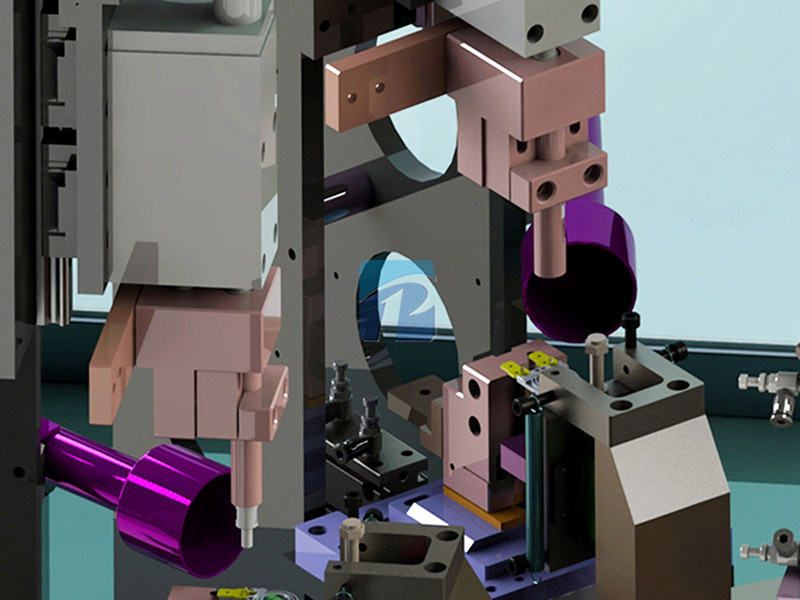

Machine introduction

Resistance welding is a process that uses an electrical current and pressure to join two or more metal parts together. The resistance welding system is designed to perform resistance spot welding on terminal parts of electrical components.

The system is designed to automatically perform the welding process once the two samples to be welded are properly positioned. The finished product is then discharged from the system.

Machine Features

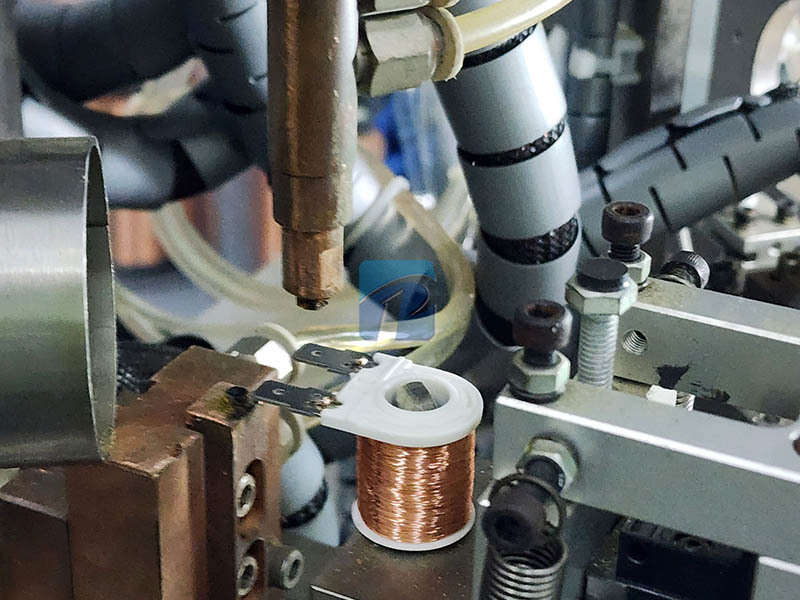

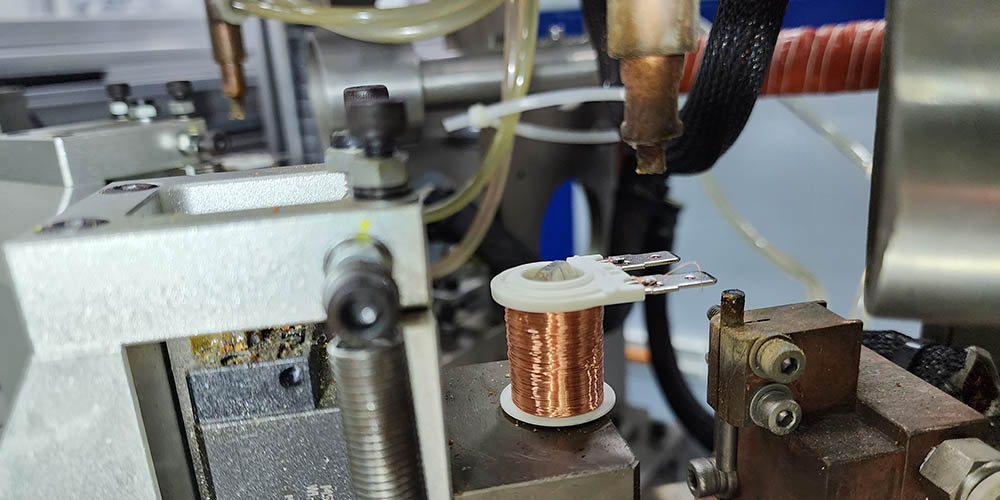

1.Automatic Operation: The resistance welding system is designed to automatically perform the welding process once the two samples to be welded are properly positioned. This improves the speed and efficiency of the welding process.

2.Stable Welding Quality: The floating mechanism of the fixture absorbs any positional differences caused by variations in the thickness of the product or electrode wear. This ensures stable and reliable welding quality.

3.Flexible Welding Options: The resistance welding system is designed to perform resistance spot welding on terminal parts of electrical components. The electric soldering machine can weld a variety of metals, including steel, aluminum, and copper.

4.Easy to Use: The soldering system is designed for ease of use, with a simple user interface that allows for quick and easy operation.