Auto Bobbin Inserting Machine For Bobbin

our Automatic Bobbin Pin Inserting Machine is a high-quality, reliable, and efficient solution for pin insertion tasks. The Auto Bobbin Inserting Machine For Bobbin's advanced technology, user-friendly features, and safety features make it an excellent choice for various manufacturing applications.

- Information

Auto Bobbin Inserting Machine For Bobbin

Machine introduction

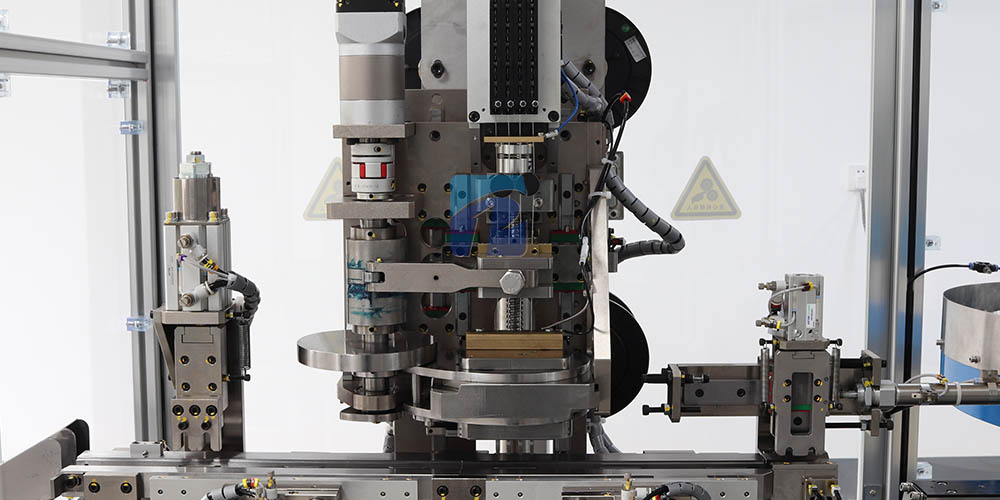

This inserting machine is designed to perform fully automatic loading, pin insertion, and bending of bobbins. The auto bobbin inserting machine can be easily integrated into an automatic winding machine production line.

Machine Features

1.Modular design: The auto bobbin inserting machine is designed with a modular structure, making it easy to maintain and use.

2.Pin cutting with chamfering function: The cutting edge of the PIN has a chamfering function, which reduces the production of foreign objects during pin insertion.

3.Adjustable pin length: The inserting machine allows for the flexibility to determine the length of the PIN. The bobbin inserting machine can accommodate multiple pin sizes and types, making it suitable for various bobbin production needs.

4.High production efficiency: The inserting machine allows for the insertion of multiple pins at once, greatly increasing production efficiency.

5.The auto bobbin inserting machine is easy to operate and maintain, with user-friendly controls and interfaces.

6.Automatic Alarm Function: The auto pin insertion machine also features an automatic alarm function for broken or bent pins. Furthermore, you can choose to add an L-shaped or T-shaped bending device to the machine to complete more complex tasks.

Technical Parameter

Model | SP-GA01 |

production efficiency | 4000PCS/H (MAX) |

| Power Source | AC380V 3P 50HZ or AC200V 3P 50/60HZ |

| Power Consumption | 1.0KW |

| Air Pressure (Mpa) | 0.45Mpa~0.65Mpa |

| Machine Size (mm) | 1500(W)×1200(D)×1800(H)mm |

| Machine Weight (mm) | About 1200KG |