Streamlining Fan Production with Motor BLDC Winding Machine

2023-07-26 14:00Introduction:

In the fast-paced world of manufacturing, efficiency and precision are paramount to stay ahead of the competition. One crucial component of many electronic devices, including fans, is the Brushless DC (BLDC) motor. As a leading manufacturer of winding machines, we have harnessed cutting-edge technology to develop the Motor BLDC Winding Machine, revolutionizing fan production. In this article, we will explore the significance of this machine and how it enhances the manufacturing process.

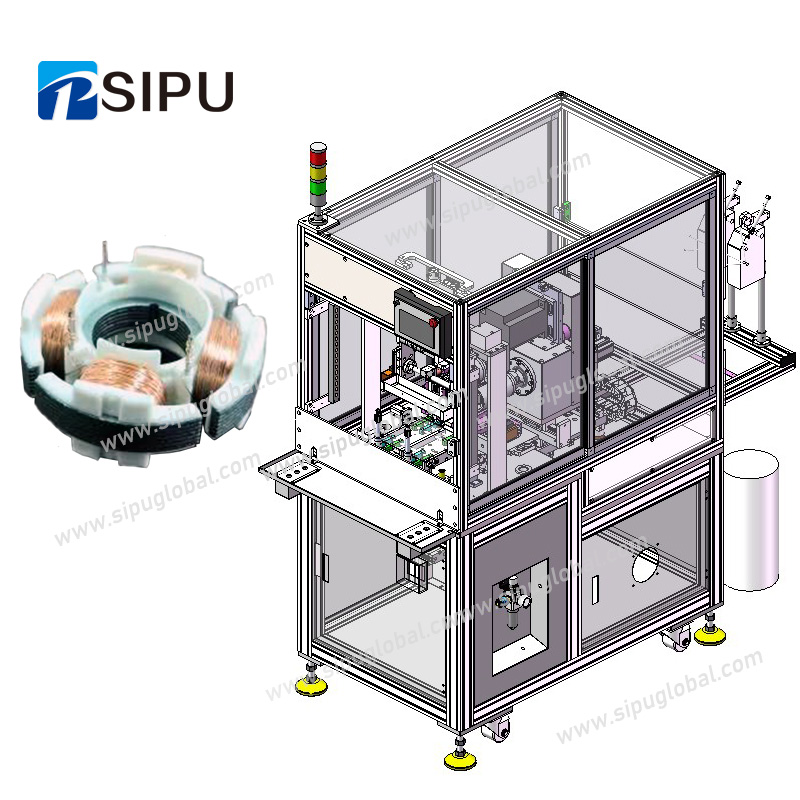

1.What is the Motor BLDC Winding Machine?

The Motor BLDC Winding Machine is a state-of-the-art piece of equipment specially designed for winding the stator coils of Brushless DC motors. BLDC motors are increasingly favored for their efficiency and reliability in various applications, such as fans, HVAC systems, and electric vehicles. The winding machine streamlines the coil winding process, ensuring consistent and precise winding for optimal motor performance.

2.How does the Motor BLDC Winding Machine improve fan production?

2.1 Enhanced Productivity:

By automating the coil winding process, the Motor BLDC Winding Machine significantly boosts productivity. Traditional manual winding methods are time-consuming and prone to errors. With our automated machine, fan manufacturers can meet increased demand, reduce lead times, and maximize overall output.

2.2 Consistent Quality:

In fan production, consistent quality is paramount to ensure smooth and noiseless operation. The Motor BLDC Winding Machine ensures uniform and accurate coil winding, reducing the risk of defects and the need for rework. This consistency translates to enhanced fan performance, increased customer satisfaction, and reduced warranty claims.

2.3 Customization Options:

Flexibility is vital in today's consumer-driven market. Our winding machine allows for easy customization of coil winding patterns and parameters, enabling manufacturers to cater to specific fan designs or performance requirements. This adaptability gives companies a competitive edge, meeting diverse customer needs effectively.

3.Key Features of the Motor BLDC Winding Machine:

3.1 Multi-Axis Control:

The machine's multi-axis control system enables precise winding at varying angles, accommodating different motor designs. This capability ensures optimal wire placement, leading to improved efficiency and reduced energy losses in the BLDC motor.

3.2 Programmable Logic Controller (PLC) Integration:

PLC integration allows for seamless automation, controlling the winding process with minimal human intervention. Manufacturers can store multiple winding programs, easily switching without lengthy setup times.

3.3 Tension Control Mechanism:

The winding machine incorporates a tension control mechanism that maintains consistent tension on the wire during winding. This feature prevents wire slippage, tangling, or breakage, further enhancing the overall quality and reliability of the BLDC motor.

Conclusion:

In conclusion, the Motor BLDC Winding Machine is a game-changer in the world of fan production. Its automation, precision, and flexibility empower manufacturers to streamline their operations and produce high-quality BLDC motors efficiently. As the demand for energy-efficient and reliable fans continues to rise, our winding machine offers a competitive advantage that keeps companies at the forefront of innovation. Embrace the technological revolution and elevate your fan production with our Motor BLDC Winding Machine.